HARVESTING AND THRESHING

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Before storing your equipment for an extended period, it is highly recommended that you clean it with a low-pressure water spray. If you notice areas where the paint is missing, sand down those areas and apply a fresh coat of paint to avoid rusting. Store the equipment in an area with minimal human and/or animal activity. You can use a tarpaulin to protect from dust and moisture.

UTILITY

Harvesting and Threshing

APPLICATION

It is suitable for harvesting rice, wheat, soybean and other cereals and oilseed crops.

COST/UNIT (India)

INR. 56,000 - 1,20,000

COST/UNIT (Bangladesh)

BDT 60,000- 1,30,000 (approx.)

DURABILITY

Vertical Reaper can be used in plains, hills, slopes, small field etc. in addition has an advantage of being small in volume, light weight, felxible and simple operation, low batch cutting and no limitation on distance. The product is very durable and can last for years under proper maintenance.

ESTIMATED CAPACITY

The field capacity of the machine is 0.15 – 0.17 ha/h

SOCIO ECONOMIC BENEFIT

The cost of operation is Rs. 1150/ha with this machine as compared to Rs. 3200/ha by traditional method. There is a saving of 90-95% in labour and time and 63% in cost of operation as compared to conventional method.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 63,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

40% up to 0.3 lakh

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Before storing your equipment for an extended period, it is highly recommended that you clean it with a low-pressure water spray. If you notice areas where the paint is missing, sand down those areas and apply a fresh coat of paint to avoid rusting. Store the equipment in an area with minimal human and/or animal activity. You can use a tarpaulin to protect from dust and moisture.

UTILITY

Harvesting and Threshing

APPLICATION

Vertical conveyor reaper is used for harvesting and windrowing of wheat and paddy crops

COST/UNIT (India)

INR. 42,000 - 90,000

COST/UNIT (Bangladesh)

BDT 75,000 (approx.)

DURABILITY

Vertical Reaper can be used in plains, hills, slopes, small field etc. in addition has an advantage of being small in volume, light weight, felxible and simple operation, low batch cutting and no limitation on distance. The product is very durable and can last for years under proper maintenance.

ESTIMATED CAPACITY

The field capacity of the machine is 0.4 ha/h at 2.5-3.5 km/h forward speed.

SOCIO ECONOMIC BENEFIT

The cost of operation is about Rs. 1600/- as against Rs. 3200/ha by traditional method.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

(for tractor>35BHP) 50% upto Rs. 63,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

Up to 50% , Up to 70% for Haor areas

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Before storing your equipment for an extended period, it is highly recommended that you clean it with a low-pressure water spray. If you notice areas where the paint is missing, sand down those areas and apply a fresh coat of paint to avoid rusting. Store the equipment in an area with minimal human and/or animal activity. You can use a tarpaulin to protect from dust and moisture.

UTILITY

Harvesting and Threshing

APPLICATION

Vertical conveyor reaper is used for harvesting and windrowing of wheat and paddy crops

COST/UNIT (India)

INR. 40,000/- (approx.)

COST/UNIT (Bangladesh)

BDT 40,000 (approx.)

DURABILITY

Vertical Reaper can be used in plains, hills, slopes, small field etc. in addition has an advantage of being small in volume, light weight, felxible and simple operation, low batch cutting and no limitation on distance. The product is very durable and can last for years under proper maintenance.

ESTIMATED CAPACITY

The effective field capacity is 0.16-0.20 ha/h

SOCIO ECONOMIC BENEFIT

cost of operation is Rs. 1400/ha.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

(for motor > 5hp) 50% upto Rs. 63,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

40% up to 0.3 lakh

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Before storing your equipment for an extended period, it is highly recommended that you clean it with a low-pressure water spray. If you notice areas where the paint is missing, sand down those areas and apply a fresh coat of paint to avoid rusting. Store the equipment in an area with minimal human and/or animal activity. You can use a tarpaulin to protect from dust and moisture.

UTILITY

Harvesting and Threshing

APPLICATION

Harvesting and Binding of Grain Crops in a single operation.

COST/UNIT (India)

INR.1,00,000 - 2,00,000/-

COST/UNIT (Bangladesh)

BDT 1-2 lakh(approx.)

DURABILITY

Vertical Reaper can be used in plains, hills, slopes, small field etc. in addition has an advantage of being small in volume, light weight, felxible and simple operation, low batch cutting and no limitation on distance. The product is very durable and can last for years under proper maintenance.

ESTIMATED CAPACITY

Harvesting and Binding of 1 Acre of field in 1 Hour, with consumption of 1 Liter Diesel only.

SOCIO ECONOMIC BENEFIT

Harvesting and Binding of Grain Crops in a single operation.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto 1.25 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

40% up to 0.3 lakh

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Before usage all the nuts and bolts of the machine should be checked and tightened if necessasary . In case of excessive/ unusual noise during operation, all bush and bearing points should be greased or oiled.

UTILITY

Harvesting and Threshing

APPLICATION

For threshing of paddy.

COST/UNIT (India)

INR. 5,500/- (approx.)

COST/UNIT (Bangladesh)

BDT 14,000- 45,000 (approx.)

DURABILITY

Useful life of machine ranges between 5 - 10 years.

ESTIMATED CAPACITY

35 kg/h

SOCIO ECONOMIC BENEFIT

It helps to reduce the drudgery involved in paddy threshing operation as bending posture is avoided and arms are not to be raised for above shoulder height as in case of traditional method i.e. beating on a platform/stone

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 30,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

70% up to 14,000

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Prior to storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

UTILITY

Harvesting and Threshing

APPLICATION

Plucking of fruits from orchard trees.

COST/UNIT (India)

INR. 600/- (approx.)

COST/UNIT (Bangladesh)

BDT 500-700 (approx.)

DURABILITY

It’s a simple tool with enough durability. Under normal working conditions one can expect the equipment to last 5 years or more.

ESTIMATED CAPACITY

420 fruits/h

SOCIO ECONOMIC BENEFIT

Damage to the fruit is avoided. · Operation is made safer as the worker does not have to climb on the tree and the chances of injury are eliminated.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 30,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

70% upto Rs. 30,000/-

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Prior to storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

UTILITY

Harvesting and Threshing

APPLICATION

These machines can also be used for harvesting onions. In some models, discs are provide in the front to cut haulm or for guiding the blade along the rows.

COST/UNIT (India)

INR. 65,000/- (approx.)

COST/UNIT (Bangladesh)

BDT 58,000-84,000 (approx.)

DURABILITY

This equipment is very durable and may last for years under proper care and maintenance.

ESTIMATED CAPACITY

0.2 ha/hour

SOCIO ECONOMIC BENEFIT

The cost of operation is Rs. 750/ha with this machine.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto 0.15 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

- 70% upto Rs. 30,000/-

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Prior to storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

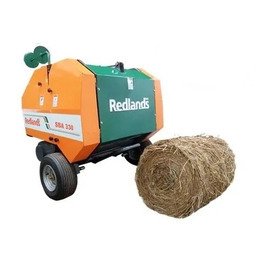

UTILITY

Harvesting and Threshing

APPLICATION

Straw balers are used for baling of straw into bales of rectangular cross section

COST/UNIT (India)

INR.2,80,000/- (approx)

COST/UNIT (Bangladesh)

BDT 3,70,000 (approx.)

DURABILITY

This equipment is very durable and may last for years under proper care and maintenance.

ESTIMATED CAPACITY

0.4 to 0.6 ha/h

SOCIO ECONOMIC BENEFIT

The cost of operation is Rs. 1200/ha.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto 0.15 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Prior to storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

UTILITY

Harvesting and Threshing

APPLICATION

It is used to harvest peanuts for the farmers and can finish digging , cleaning, and peanut stalks laying in one operation, which could decrease the labor intensity, lessen harvesting cost, and improve working efficiency.

COST/UNIT (India)

INR. 35,000

COST/UNIT (Bangladesh)

BDT 50,000 (approx.)

DURABILITY

This equipment is very durable and may last for years under proper care and maintenance.

ESTIMATED CAPACITY

0.26 ha/h

SOCIO ECONOMIC BENEFIT

The cost of operation is Rs. 3,885/ha.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto 0.15 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Prior to storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

UTILITY

Harvesting and Threshing

APPLICATION

For harvesting Turmeric Rhizomes

COST/UNIT (India)

INR. 22,000-25,000/

COST/UNIT (Bangladesh)

BDT. 35,000

DURABILITY

This equipment is very durable and may last for years under proper care and maintenance.

ESTIMATED CAPACITY

0.36 ha/h

SOCIO ECONOMIC BENEFIT

The cost of digging of turmeric with the implement is Rs. 4,830/ha.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto 0.2 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Prior to storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

UTILITY

Harvesting and Threshing

APPLICATION

They are used for harvesting groundnut crop.

COST/UNIT (India)

INR.80,000/-

COST/UNIT (Bangladesh)

BDT. 80,000-90,000

DURABILITY

This equipment is very durable and may last for years under proper care and maintenance.

ESTIMATED CAPACITY

0.16-0.21 ha/h

SOCIO ECONOMIC BENEFIT

The cost of operation is Rs. 3,200/ha

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto 0.2 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

42% up to 1,30,000

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung on to the equipment. Prior to storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing.

UTILITY

Harvesting and Threshing

APPLICATION

It is suitable for harvesting rice, wheat, soybean and other cereals and oilseed crops.

COST/UNIT (India)

INR. 1,20,000

COST/UNIT (Bangladesh)

BDT 45,000- 50,000 (approx.)

DURABILITY

This equipment is very durable and may last for years under proper care and maintenance.

ESTIMATED CAPACITY

0.25-0.30 ha/h

SOCIO ECONOMIC BENEFIT

The cost of operation is Rs. 645.77/ha

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto 0.63 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

Up to 50% , Up to 70% for Haor areas

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Lubricate cylinder and fan bearings with good-quality general purpose grease every 25 hours of operation. Periodically apply a small amount of oil to all hinge points. Inspect the machine regularly for loose, worn, or damaged peg teeth, concave bars, cylinder, discharge paddles, and other parts, and tighten, repair, or replace them immediately. Missing bolts or nuts must also be replaced.

UTILITY

Threshing

APPLICATION

Open drum thresher applied to threshing of the paddy

COST/UNIT (India)

INR 8700

COST/UNIT (Bangladesh)

BDT 8500

DURABILITY

This durable equipment may last for years under proper care and maintenance.

ESTIMATED CAPACITY

Approx. 0.4-0.5tons/hour and thresher efficiency is more than 95 %

SOCIO ECONOMIC BENEFIT

The wheels provided in the open drum thresher help in the easy movement of the thresher from door to door and the field.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

Up to 50%

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

50% up to 3.5 lakh

AGENCIES INVOLVED (India)

Directorate of Agriculture/ Dept. of Agricultural Engineering, Office of Dy. Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung to the equipment. Before storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

UTILITY

Threshing and harvesting

APPLICATION

Mini-combine harvester was used for rice harvesting cleaning tasks as well in a single operation

COST/UNIT (India)

INR. 4,90,000 (approx.)

COST/UNIT (Bangladesh)

BDT. 6,00,000 (approx.)

DURABILITY

Extremely Durable and reliable equipment. Under proper care and maintenance, the product can last for more than 10 years.

ESTIMATED CAPACITY

2.5 ha/day

SOCIO ECONOMIC BENEFIT

Labor could be saved 65% for using a mini-combine harvester over manual harvesting

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

Up to 50%

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

Up to 50% , Up to 70% for Haor areas

AGENCIES INVOLVED (India)

Directorate of Agriculture/ Dept. of Agricultural Engineering, Office of Dy. Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI), Bangladesh Agricultural University

MAINTENANCE

Proper observation of the basket. If the basket broke or is damaged quick repairing should be done immediately.

UTILITY

Harvesting

APPLICATION

Apply to harvest mangoes

COST/UNIT (India)

INR 300 per piece

COST/UNIT (Bangladesh)

BDT 300 per piece

DURABILITY

It’s a simple tool with enough durability. Under normal working conditions, one can expect the equipment to last 5 years or more.

ESTIMATED CAPACITY

150–200 kg/h

SOCIO ECONOMIC BENEFIT

The mango can be harvested by the machine at a 20% higher speed than that of the traditional methods

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

N/A

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Directorate of Agriculture/ Dept. of Agricultural Engineering, Office of Dy. Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University

MAINTENANCE

Clean your equipment after each use. Remove dirt and debris that have clung to the equipment. Before storage, give your equipment a once over, look for signs of wear and/or damage and make the necessary maintenance/repairs if required before storing

UTILITY

Harvesting

APPLICATION

Apply to harvest potatoes

COST/UNIT (India)

INR. 65,000 (approx.)

COST/UNIT (Bangladesh)

BDT. 72,000 (approx.)

DURABILITY

This durable equipment may last for years under proper care and maintenance.

ESTIMATED CAPACITY

3 ha/day

SOCIO ECONOMIC BENEFIT

Save 65% cost and 70% labor

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50%

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

58%

AGENCIES INVOLVED (India)

Directorate of Agriculture/ Dept. of Agricultural Engineering, Office of Dy. Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural University