POST HARVEST

MAINTENANCE

Before usage, all the nuts and bolts of the machine should be checked and tightened if necessary. In case of excessive/ unusual noise during operation, all bush and bearing points should be greased or oiled.

UTILITY

Post Harvest

APPLICATION

For cleaning paddy crop post harvesting

COST/UNIT (India)

INR.5000/- (approx.)

COST/UNIT (Bangladesh)

BDT 8,000 -16,000 (approx.)

DURABILITY

Useful life of machine is 10 years.

ESTIMATED CAPACITY

242 kg/hr

SOCIO ECONOMIC BENEFIT

This machine can be easily operated as there no need of waiting for air flow as required in traditional cleaning. · This machine can be operated under shade or in the workshop where grain cannot be damaged due to rain etc

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 30,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

50-70% up to 16,000

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI), Bangladesh Sugarcrop Research Institute

MAINTENANCE

Store in a dry and shady area to avoid rusting. Occasionally oiling of the tyres will help with the smooth functioning of the equipment.

UTILITY

Post Harvest

APPLICATION

Carrying of agricultural materials

COST/UNIT (India)

INR. 2,000/- (approx.)

COST/UNIT (Bangladesh)

BDT 4800 (approx.)

DURABILITY

The expected life of the tool is 5 to 10 years.

ESTIMATED CAPACITY

100 kg of load easily carried out by wheel barrow

SOCIO ECONOMIC BENEFIT

A large amount of material can be carried from one place to another with less drudgery.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 75,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI), Bangladesh Sugarcrop Research Institute

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

Cleaning and Grading of Cumin

COST/UNIT (India)

INR. 36,000/-

COST/UNIT (Bangladesh)

BDT 71,000 (approx.)

DURABILITY

The product comes with a warranty of 1 year and can easily last upto 5 years.

ESTIMATED CAPACITY

Capacity: 50 kg/hr with an efficiency of 75 % to 80 %

SOCIO ECONOMIC BENEFIT

Operating cost : 37.50/ hr, Output : 0.75/ kg

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 50,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

70% up to 70,000

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI), Bangladesh Sugarcrop Research Institute

MAINTENANCE

Clean the sheller with a dry cloth after each use. Store in a dry place to avoid rusting and increase the life of the sheller.

UTILITY

Post Harvest

APPLICATION

Suitable for shelling maize from dehusked cobs.

COST/UNIT (India)

INR. 100/-

COST/UNIT (Bangladesh)

BDT 100-170 (approx.)

DURABILITY

The Maize Sheller is a handy and durable product and can easily last for a year before it needs to be replaced.

ESTIMATED CAPACITY

The capacity of sheller is 15-20 kg/h

SOCIO ECONOMIC BENEFIT

The productivity of the workers increases 1.6 times while using this equipment in comparison to the traditional practice of shelling using a sickle or hands. Chance of Injury to fingers is eliminated using these tools.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

N/A

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

25% subsidy

AGENCIES INVOLVED (India)

Directorate of Agriculture/ Dept. of Agricultural Engineering, Office of Dy. Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

This equipment is used for dehusking and shelling the maize cobs in a single pass.

COST/UNIT (India)

INR. 85,000/- (approx.)

COST/UNIT (Bangladesh)

BDT 1,10,000 (approx.)

DURABILITY

The excpected life of this equipment is around 8 - 10 years with a payback period of 0.74 years.

ESTIMATED CAPACITY

The output of machine is 800kg/hr. Operation efficiency for Dehusking 99% and Shelling 97-98%.

SOCIO ECONOMIC BENEFIT

The cost of operation of this machine is Rs. 500/t against Rs. 1500/t by traditional method. Savings in cost of operation : 44 Rs/Q (labour cost), Time saving - 2 hr/Q.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 75,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60-70% up to 1 lakh

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI),

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

The equipment is used for extraction of Aloe Vera Juice.

COST/UNIT (India)

INR. 75,000/- (approx.)

COST/UNIT (Bangladesh)

BDT 75,000 (approx.)

DURABILITY

This comes with an year of warranty and is a long lasting product.

ESTIMATED CAPACITY

Output Capacity : 100 - 150 Litres/ Day

SOCIO ECONOMIC BENEFIT

Cost of operation: Rs. 30/litre, Savings in cost of operation: Rs. 10/litre (Labour Cost), Time saving:0.3 hr/litre

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 1,80,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

The solar panels/ reflectors needs to be cleaned on a regular basis to continue being effective. The drying area also needs to be thoroughly cleaned after each use.

UTILITY

Post Harvest

APPLICATION

Drying of agricultural prodcuts

COST/UNIT (India)

INR. 15,000/- (approx.)

COST/UNIT (Bangladesh)

BDT 18,000(approx.)

DURABILITY

A standard equipment comes with a warranty of 10 years, although the best panels can last upto 25 years.

ESTIMATED CAPACITY

The temperature inside can reach upto 80˚C on sunny days.

SOCIO ECONOMIC BENEFIT

Solar drying allows preservation of food, fruits and vegetables for a longer period. Time required for drying is comparatively less than open air drying. Quality of product is maintained by avoidining direct exposure to solar radiations.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% utpo Rs. 3,50,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 3.5 lakh

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

After each use, disconnect the power and brush off the dust. Look for visible damage and replace any damaged parts.

UTILITY

Post Harvest

APPLICATION

Grinding of wheat, corn, teff, sorghum, millet etc.

COST/UNIT (India)

INR. 17,000/- (approx.)

COST/UNIT (Bangladesh)

BDT 18,000 (approx.)

DURABILITY

Grinding mills can easily last a period between 5 to 10 years depending on their maintenance and usage.

ESTIMATED CAPACITY

30 - 90Kg/Hour

SOCIO ECONOMIC BENEFIT

Operating cost - Rs. 175/Q of raw material

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 1,50,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

50% up to 18,000

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

After each use, disconnect the power and brush off the dust. Look for visible damage and replace any damaged parts.

UTILITY

Post Harvest

APPLICATION

It is used to for grinding of cereals, pulses and some spices like coriander, cumin etc.

COST/UNIT (India)

INR. 19,000/- (approx.)

COST/UNIT (Bangladesh)

BDT. 1,80,000

DURABILITY

Grinding mills can easily last a period between 5 to 10 years depending on their maintenance and usage.

ESTIMATED CAPACITY

10-20 kg/hr for flour or powder making, 50-70 kg/hr for dal making

SOCIO ECONOMIC BENEFIT

Approx. 80 % operation time is reduced compare to traditional method

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 1,50,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 1.8 lakh

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

This technique is used for extraction of Kernel oil from Apricot seeds or stones.

COST/UNIT (India)

INR. 55,000/- (decorticator), INR. 60000/- (table oil expeller) and INR. 30000/- (oil filter press)

COST/UNIT (Bangladesh)

BDT. 1,00,000 (approx.)

DURABILITY

This product comes with a 1 year warranty and is can easily last for a period between 5 - 10 years.

ESTIMATED CAPACITY

Decotricator: 80-100kg/hr, Table Oil Expeller: 5 kg kernel/hr and Oil Filter Press: 2 kg oil/hr.

SOCIO ECONOMIC BENEFIT

Reduction of cost (Rs. 72/lt) and higher recovery by 37%. Recovery of oil using modern technique is 1408 litres/ 10 tons of apricot kernel. Whereas, the traditonal technique could only extract 1254 litres.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 3,00,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 3 lakhs

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

This equipment is used for threshing and pearling of finger millets.

COST/UNIT (India)

INR. 12,000/- (approx.)

COST/UNIT (Bangladesh)

BDT. 5,40,000

DURABILITY

The product is durable for and comes with a warranty of 2 to 3 years. One can expect this tool to last for an expected period of 5+ years based on its usage and maintenance.

ESTIMATED CAPACITY

Threshing capacity: 30-35 kg/hr (98.1% efficiency), Pearling capacity: 60-65 kg/hr (97.9% efficiency)

SOCIO ECONOMIC BENEFIT

Operational cost: Rs.3.60/hr, Time saving: 5 h/day, Improvement in storage life: 180 to 200 days

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 75,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 5.4 lakhs

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Inspect the power cord and the water inlet pipe before each use. Never overload the drum and clean in smaller portions for more effective results. After using the equipment clean the rotary drum and check for any signs of damage. Keep in a dry safe area for avoiding rusting.

UTILITY

Post Harvest

APPLICATION

This equipment is suitable for cleaning fruits and vegetables.

COST/UNIT (India)

INR 80,000-120,000 (for different capacity model)

COST/UNIT (Bangladesh)

BDT 1,00,000 -2,50,000 (for different capacity model)

DURABILITY

This product comes with a 1 year warranty and is can easily last for a period between 5 - 10 years.

ESTIMATED CAPACITY

Output capacity 1 - 6 Q/hr, 20 kg/batch, Washing efficiency - 90.2-95.5%. Production Capacity - Apple 30T/h, Watermelon 10T/h, Carrot 8T/h, Orange 35T/h.

SOCIO ECONOMIC BENEFIT

Unit cost of production is Rs. 2-15/Q

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 60,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

70% of cost

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

This is a simple machine which doesn’t require much of maintenance. Check for initial signs of wear/ damage to the equipment and take the required actions before seed oil extraction. Occasionaly, lubvricate the motor parts for a smoother functioning of the machine. Post usage wipe off the dust with the help of a clean cloth and store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

This equipment is useful for grading of spherical fruits into 3 to 4 grades with 70 to 85% grading efficiency.

COST/UNIT (India)

INR. 3 – 6.5 lakh(approx.)

COST/UNIT (Bangladesh)

BDT. 3 – 6.5 lakh(approx.)

DURABILITY

Grader sytems comes with a warrantly of 1- 2 years depending on the model.

ESTIMATED CAPACITY

Capacity – 8 - 10 t/day, Efficiency – 70 – 85%

SOCIO ECONOMIC BENEFIT

Save time and labour, Operating cost – Rs. 125/h. Results in increased capacity of 1.5 times over conventional method.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 50,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

70% of the cost

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Check for signs of damage and make the necessary replacement before using the equipment. Oiling of the motor parts for a smoother functioning of the machine shall be done on a regular basis. Post usage wipe off the dust with the help of a clean cloth. Store the equipment in a dry shady area to avoid rusting and damage.

UTILITY

Post Harvest

APPLICATION

This equipment is useful for dehusking and splitting of pigeon pea, black gram, green gram and lentil

COST/UNIT (India)

INR. 32,000 – 2,15,000

COST/UNIT (Bangladesh)

BDT. 200000

DURABILITY

The product is durable and comes with a warranty of 2 to 3 years. One can expect this tool to last for an expected period of 5+ years based on its usage and maintenance.

ESTIMATED CAPACITY

This mill has capacity of 100 kg/h, dal recovery of 72% and broken yield between 3-5%.

SOCIO ECONOMIC BENEFIT

Approx. 80 % operation time is reduced compare to traditional method. Operating cost - Rs. 175/q of raw material (Pigeon pea) and Rs. 220/h

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% utpo Rs. 1,50,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 1.5 lakh

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Sonargaon Flour & Dal mills ltd.

MAINTENANCE

Check for signs of damage and make the necessary replacement before using the equipment. Oiling of the motor parts for smoother functioning of the machine shall be done on a regular basis. Post usage wipe off the dust with the help of a clean cloth. Store the equipment in a dry shady area to avoid rusting and damage.

UTILITY

Post Harvest

APPLICATION

This equipment is useful for cleaning, shelling, separating and polishing of paddy crops.

COST/UNIT (India)

INR. 25,000/-

COST/UNIT (Bangladesh)

BDT. 10,000 – 15,000

DURABILITY

The product is durable for and comes with a warranty of 2 to 3 years. One can expect this tool to last for an expected period of 5+ years based on its usage and maintenance.

ESTIMATED CAPACITY

2Ton/ Day

SOCIO ECONOMIC BENEFIT

Farmer is expected to rise 20-25% of the capital as margin money. Expected profit per year 10 Lakh.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto 2,40,000/-

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 2.4 lakhs

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI),

MAINTENANCE

After each use, disconnect the power and brush off the dust. Look for visible damage and replace any damaged parts.

UTILITY

Post Harvest

APPLICATION

This machine is used to seal plastic bags using heat

COST/UNIT (India)

INR. 1,000/-

COST/UNIT (Bangladesh)

BDT. 2000

DURABILITY

This product comes with a 3-month warranty.

ESTIMATED CAPACITY

Seals 20-25 bags per minute.

SOCIO ECONOMIC BENEFIT

Widely used for packaging of products to be sold directly in the market.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 3,00,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

10-15% of the cost

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

After each use, disconnect the power and brush off the dust. Look for visible damage and replace any damaged parts. Will require occasional lubrication for smooth functioning.

UTILITY

Post Harvest

APPLICATION

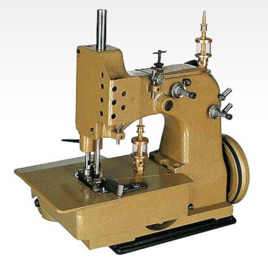

This equipment is used for stitching of all kinds of Multi-Wall Paper, Jute, Woven Polypropylene bags, etc.

COST/UNIT (India)

INR. 5,000/-

COST/UNIT (Bangladesh)

BDT. 9,000 -13,000 (for different capacity model)

DURABILITY

Fully automatic lubrication with oil recycling system which ensures long life of machine.

ESTIMATED CAPACITY

1600 -1800 stitches per minute 5 to 8 Bags per minute.

SOCIO ECONOMIC BENEFIT

Saves considerable time and labor involved in the process of stitching.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 3,00,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

50% of cost

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

The equipment is used to remove dust, dirt, straw, chaff, etc. and can grade the cereals and pulses.

COST/UNIT (India)

INR. 20,000/-

COST/UNIT (Bangladesh)

BDT. 20,000-45,000

DURABILITY

The product comes with a warranty of 1 year and can easily last upto 5 years.

ESTIMATED CAPACITY

Output Capacity: 330-800kg/ hr. The cleaning efficiency of this equipment is 99%

SOCIO ECONOMIC BENEFIT

Value addition of about Rs. 400/ Ton

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% upto Rs. 1,00,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

50% up to 2 lakhs

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI),

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

This technique is used for extraction of Mustard oil.

COST/UNIT (India)

INR. 80,000 - 2,00,000/-

COST/UNIT (Bangladesh)

BDT. 50,000 - 1,90,000 (approx.)

DURABILITY

This product comes with a 1 year warranty and is can easily last for a period between 5 - 10 years.

ESTIMATED CAPACITY

Vary from 3-20 Ton/ Day

SOCIO ECONOMIC BENEFIT

Mills are an efficient method of oil extraction and can help reduce drudgery and labour cost substantially.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 3,00,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural university

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

This technique is used for extraction of Sunflower oil.

COST/UNIT (India)

INR. 70,000 - 1,50,000/-

COST/UNIT (Bangladesh)

BDT. 1,10,00 – 1,60,000 (approx.)

DURABILITY

This product comes with a 1 year warranty and is can easily last for a period between 5 - 10 years.

ESTIMATED CAPACITY

400-500 Kg/ Day

SOCIO ECONOMIC BENEFIT

Mills are an efficient method of oil extraction and can help reduce drudgery and labour cost substantially.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 3,00,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 3,00,000

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Agricultural university

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipe off the equipment with the help of a clean cloth. Store in a dry shady area.

UTILITY

Post Harvest

APPLICATION

This technique is used for extraction of Groundnut oil.

COST/UNIT (India)

INR. 1,00,000 - 1,65,000/-

COST/UNIT (Bangladesh)

BDT. 70,000 – 2,40,000

DURABILITY

This product comes with a 1 year warranty and is can easily last for a period between 5 - 10 years.

ESTIMATED CAPACITY

1-5 Ton/ Day

SOCIO ECONOMIC BENEFIT

Mills are an efficient method of oil extraction and can help reduce drudgery and labour cost substantially.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

60% upto Rs. 3,00,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 3,00,000

AGENCIES INVOLVED (India)

Nodal Agency - Directorate of Agriculture/ Dept. of Agricultural Engineering (Uttarakhand & Assam) Implementation Agency - Office of Dy. Director/Joint Director/ Executive Engineer/ Assitant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI)

MAINTENANCE

Before usage, all the nuts and bolts of the machine should be checked and tightened if necessary. In case of excessive/ unusual noise during operation, all bush and bearing points should be greased or oiled.

UTILITY

Post Harvest

APPLICATION

Briquetting machines used for the densification of agricultural residues are of various types.

COST/UNIT (India)

INR 1 lakh

COST/UNIT (Bangladesh)

BDT 1 lakh

DURABILITY

The product comes with a warranty of 1-2 years and can easily last up to 5 years.

ESTIMATED CAPACITY

Average 39 kg/h

SOCIO ECONOMIC BENEFIT

Reduces the post-harvest residues. The materials were compressed to a higher density of about 15.5 times.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% up to 1,00,000

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

50% up to 0.4 lakh

AGENCIES INVOLVED (India)

Agricultural university, KVKs, Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI),

MAINTENANCE

Store in a dry and shady area to avoid rusting.

UTILITY

Post Harvest

APPLICATION

Applying for drying paddy crops after harvesting

COST/UNIT (India)

INR 15,000

COST/UNIT (Bangladesh)

BDT 15,000

DURABILITY

The product comes with a warranty of 1 year and can easily last up to 5 years.

ESTIMATED CAPACITY

1 q -2.5 q per 8-10 hours

SOCIO ECONOMIC BENEFIT

Paddy dryer reduces drying loss of paddy significantly. The low-cost BAU-STR dryer would be an alternative effective drying technology to save 1.4 MMT of paddy by reducing 2.7% losses of national production (51.87 MMT)

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

N/A

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Agricultural university, KVKs, Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI), Bangladesh Agricultural university

MAINTENANCE

Lubricate the motor parts and joints for a smoother functioning and desired outcome. Post usage wipes off the equipment with the help of a clean cloth.

UTILITY

Post Harvest

APPLICATION

Boiler mainly used in rice or other food grain

COST/UNIT (India)

INR 96,000 – 1,00,000

COST/UNIT (Bangladesh)

BDT 1,00,000

DURABILITY

One can expect this tool to last for an expected period of 5+ years based on its usage and maintenance.

ESTIMATED CAPACITY

8 q/day

SOCIO ECONOMIC BENEFIT

It can be made of locally available materials, has high burning efficiency, and less pollution. Less time consumption for steaming, it is safe and clean.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

N/A

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

N/A

AGENCIES INVOLVED (India)

Agricultural university, KVKs, Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI), Bangladesh Agricultural university

MAINTENANCE

After each use, disconnect the power and brush off the dust. Look for visible damage and replace any damaged parts.

UTILITY

Post Harvest

APPLICATION

Application of the coconut dehusking machine to peels off the coconut husk from the coconut fruit

COST/UNIT (India)

INR 2500-3000

COST/UNIT (Bangladesh)

BDT 2000-2500

DURABILITY

This durable equipment may last for years under proper care and maintenance.

ESTIMATED CAPACITY

200-500 nuts / hours

SOCIO ECONOMIC BENEFIT

The machine is appeared to be feasible, pollution less, economic. The number of nuts produced per hour depends upon the slack time and speed of roller units, which highly reduces the labor and time.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% up to 1.53 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

70% up to 1.50 lakh

AGENCIES INVOLVED (India)

Agricultural university, KVKs, Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI), Bangladesh Agricultural university

MAINTENANCE

After using the machine, it should be properly cleaned, and the rotating parts should be greased for the long-term durability of the machine

UTILITY

Post Harvest

APPLICATION

Apply for polishing of turmeric.

COST/UNIT (India)

INR 55,000

COST/UNIT (Bangladesh)

BDT 30,000

DURABILITY

This equipment is very durable and may last for many years under proper care and maintenance.

ESTIMATED CAPACITY

65–90 kg/h

SOCIO ECONOMIC BENEFIT

It requires 20 minutes only to complete a batch of turmeric polishing and the machine is ready for the next batch, so it required a very small period.

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

50% up to 1.53 lakh

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

40% up to 0.5 lakh

AGENCIES INVOLVED (India)

Agricultural university, KVKs, Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI),

MAINTENANCE

After using the machine, it should be properly cleaned, and the rotating parts should be greased for the long-term durability of the machine

UTILITY

Post Harvest

APPLICATION

Apply for potato grading

COST/UNIT (India)

INR 40,000

COST/UNIT (Bangladesh)

BDT 40,000

DURABILITY

This equipment is very durable and may last for many years under proper care and maintenance

ESTIMATED CAPACITY

1.3 ton/h

SOCIO ECONOMIC BENEFIT

In a shorter time and at a lower cost the potato can be graded in three sizes

SUBSIDIES/ASSISTANCE FROM GOVT. (India)

Up to 50%

SUBSIDIES/ASSISTANCE FROM GOVT. (Bangladesh)

60% up to 0.5 lakh

AGENCIES INVOLVED (India)

Agricultural university, KVKs, Director/Joint Director/ Executive Engineer/ Assistant Engineer (Agriculture)

AGENCIES INVOLVED (Bangladesh)

Bangladesh Agri Research Institute (BARI), Bangladesh Rice Research Institute (BRRI),